Taiwan is now in the “dog days of summer,” and as a result of its consistently rising electricity consumption, energy efficiency and green energy are becoming increasingly important. In order to support all sectors in their efforts to conserve energy and reduce carbon emissions, MEAN WELL, the top brand of standard power supplies in the world, has long been dedicated to improving product performance. In particular, in recent years, as more industries have felt the effects of ESG, the demand for energy-efficient and green energy products has increased significantly. Through the versatile combination of 3 N System Solutions, MEAN WELL’s wide range of solutions may assist clients in fast achieving their energy-saving objectives.

Here, “3” stands for Rack Power, Modular Power, and System Power, and “N” stands for the virtually limitless ways that MEAN WELL’s products can be combined and customized. The latest generation of industrial-grade chargers and inverters, bidirectional power supplies, and energy-saving burn-in system solutions from MEAN WELL have evolved into energy-saving instruments for all industries under the 3 N System Solutions framework.

3 N system solutions by MEAN WELL

Eris Wu, the MEAN WELL company’s chief technical officer: “Peak-shaving and valley-filling of the energy storage system and bidirectional power conversion can store energy during off-peak hours and discharge during peak hours, so as to most effectively allow for no distinct peaks or lows, if an enterprise wants to lower electricity bills while taking into account power stability and net-zero carbon emissions. The only way to significantly cut electricity costs, energy use, and carbon emissions is to lessen the strain on the power system.” Businesses must act quickly to take preventative steps when electricity prices are set to increase.

MEAN WELL’s new generation of industrial-grade chargers and inverters has complete specifications, ranging from low to high wattage, fully satisfying requirements for battery charging, green energy storage, power backup, mobile device charging, mobile power supply, and stationary energy storage. REDUNDANT, PORTABLE POWER PRODUCTS ARE BECOMING READILY AVAILABLE

In general, alternating current is produced by fuel generators to meet demand for power in areas without alternating current. But in addition to being noisy and polluting, generators also go against environmental protection; DC-AC inverters are crucial in applications for green energy. Accordingly, MEAN WELL’s NTS/NTU series of inverters and NPB series of chargers are combined with customer battery systems to address power supply issues in diverse locations without AC power and serve as battery-based UPS backup power supplies.

According to Tony Hsieh, Section Manager of MEAN WELL’s Technical Service Center, customers can obtain the system solutions they require fast as long as they choose items from the company’s website in accordance with the charging current and load requirements for the application.

To broaden the range of applications even more, MEAN WELL keeps creating devices that are smaller and more flexible to deploy. For instance, as a result of the COVID-19 epidemic, hospitals predominantly adopted a lot of mobile disinfection lamps. MEAN WELL’s miniaturized products may be seamlessly integrated with the main body of these mobile systems to provide mobile charging capabilities and enhance the mobility of devices. Similar to how medical carts, floor-cleaning robots, and other equipment might profit from MEAN WELL power supply’ convenience. Additionally, applications like burners can quickly set voltage and current thanks to the integration of software, which makes them more practical.

CONVERT RECYCLE POWER FROM BIDIRECTIONAL POWER SUPPLIES MEANS WELL Battery research and testing primarily use bidirectional power supplies. Battery use has increased quickly in recent years due to the advancement of green energy and sustainable development. Thus, a good battery can aid in energy conservation and carbon reduction. Through maintain the battery’s level of function and performance from battery manufacture to shipment, the charging and discharging processes must be repeated.

In the past, charging and discharging required the use of an inverter and a charger separately. The temperature of the working environment would increase as a result of the heat energy dissipating into the air as a result of the discharge through resistance. The bidirectional power supply from MEAN WELL includes an inverter and a charger, as the name implies. In addition to discharging the DC battery in the opposite direction smoothly within 1ms, it can also charge the DC battery through AC. The DC energy is recovered by the battery or load terminal and transformed into AC power before being delivered straight into the mains grid.

“Thus, the entire charge and discharge curve may be graphed using the 1 ms seamless switching function. Equipment charging and discharging expenses, space requirements, and maintenance tasks can all be made easier. Additionally, heat dissipation is significantly reduced, limiting the amount of temperature rise in the workplace and allowing for less air conditioning, all of which contribute to lower power consumption “said Simon Kuo, the Product Strategy Center’s Product Manager.

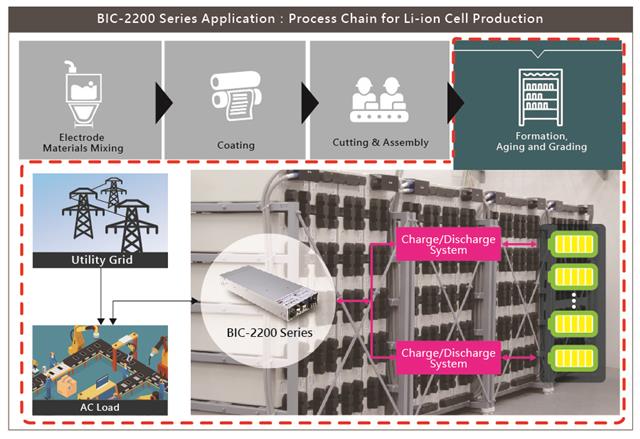

Since its debut, MEAN WELL’s BIC-2200 series of Bidirectional Power Supplies has received the best reviews. Complete safety certification is another reason why domestic and international clients favor MEAN WELL products in addition to the aforementioned benefits. According to reports, a large number of well-known ATE manufacturers have chosen MEAN WELL’s bidirectional power supply to satisfy the stringent standards of standard battery testing set by European, American, and Japanese automakers.

An illustration of the production of lithium batteries utilizing the BIC-2200 series

The energy-saving burn-in system has an energy-saving rate of up to 80%. Mean Well works to reduce its own electricity consumption while offering a variety of energy-saving goods to its clients. For the burn-in process , for instance, MEAN WELL created and planned its Energy Recovery System (ERS) ERG-5000, which reuses and recycles the electricity initially utilized for burn-in testing.

An energy-saving rate of up to 81 percent is possible by using the mains AC to supply a small portion of the insufficient electric energy. ERS lowers GHG and hazardous gas emissions while saving electricity.

The Environmental Protection Administration’s “3rd Enterprises Environmental Protection Award” has recognized MEAN WELL for using this energy-saving burn-in technology. In order to assist everyone save energy and cut carbon emissions, MEAN WELL has now expanded its use of the ERS beyond internal purposes.